De-risk and Deliver Your Multi-Residential Projects On Time

Avoid delays, cost overruns, and simplify project design to deliver a defect free build

Logicwall Benefits

No supply or delivery delays

Lower P&G Costs

Acoustic compliance

Fire compliance

AFS Install Service

Defect Free Handover

No supply or delivery delays

Lower P&G Costs

Defect Free Handover

On time, on budget, and defect free shouldn’t just be a dream.

What should happen:

- Construction flows as planned

- P&G costs remain stable

- Uncomplicated project management

What always happens:

- Deliveries arrive late creating delays

- Material prices suddenly increase

- There’s too many parties to manage

- Find remedials, defects in building on completion

We Help Builders

De-risk and Deliver Projects on Time

Building with AFS LogicWall makes a lot of your day-to-day issues go away

We Help Builders

De-risk and Deliver Projects on Time

Building with AFS LogicWall makes a lot of your day-to-day issues go away

• Lump sum pricing to help manage your cost forecasts

• Full supply and installation package

• Reduces intertenancy wall parties/contractors from 5 to 1

• De-risk project costs and timeline

• Reduce project management time

• Lump sum pricing to help manage your cost forecasts

• Full supply and installation package

• Reduces intertenancy wall parties/contractors from 5 to 1

• De-risk project costs and timeline

• Reduce project management time

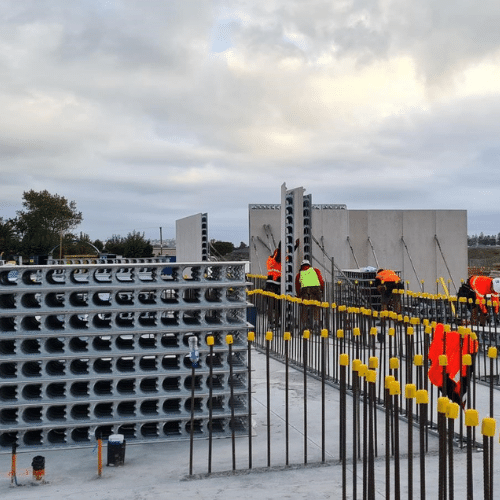

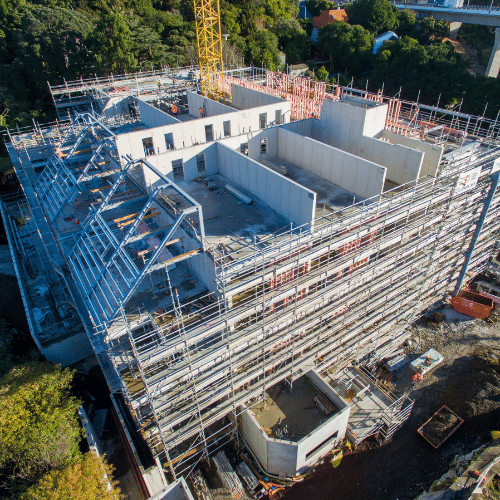

Project – Thompson Park Apartments

Product Used

AFS Logicwall®

Project Type

Apartments

Location

Status

Completed

This 5 storey apartment complex includes 104 apartments set in Mount Wellington, Auckland.

We used our Logicwall® product for the intertenancy walls, stair shafts, and blade walls and worked with Clearwater Construction to build them.

This 5 storey apartment complex includes 104 apartments set in Mount Wellington, Auckland.

We used our Logicwall® product for the intertenancy walls, stair shafts, and blade walls and worked with Clearwater Construction to build them.

Your De-Risking Pathway

01

Consult

Discuss with us your projects challenges, specific needs and timeline.

02

Inform

AFS will present an AFS Wall markup, indicative install durations, and a no obligation proposal and scope of works.

03

Decide

You then have the confidence that you are making a well informed decision on what the best intertenancy wall system is for your project.

Avoid the nightmares of exploding project costs and timelines

When building your next multi-residential project you need a reliable intertenancy wall solution. One that will help you run on time, at or under budget, and without any defects when it’s time for handover. Avoid expensive delays, material price increases, and the headaches of managing multiple contractors.

Relying on the wrong intertenancy wall systems can put your business at risk. You deserve to protect your projects timeline and P&G costs. All the planning you do should pay dividends, not end up in the bin when there’s a delay or materials shortage.

The AFS LogicWall Solution

View Gallery

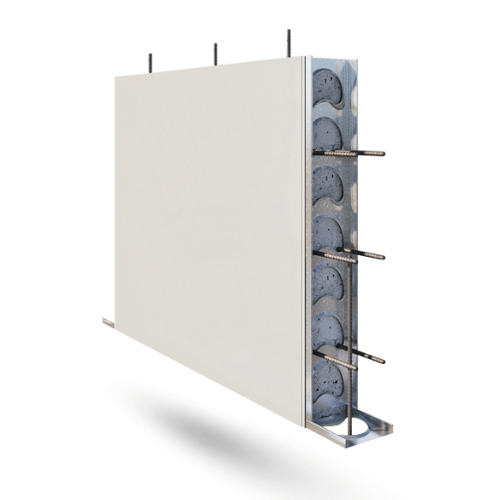

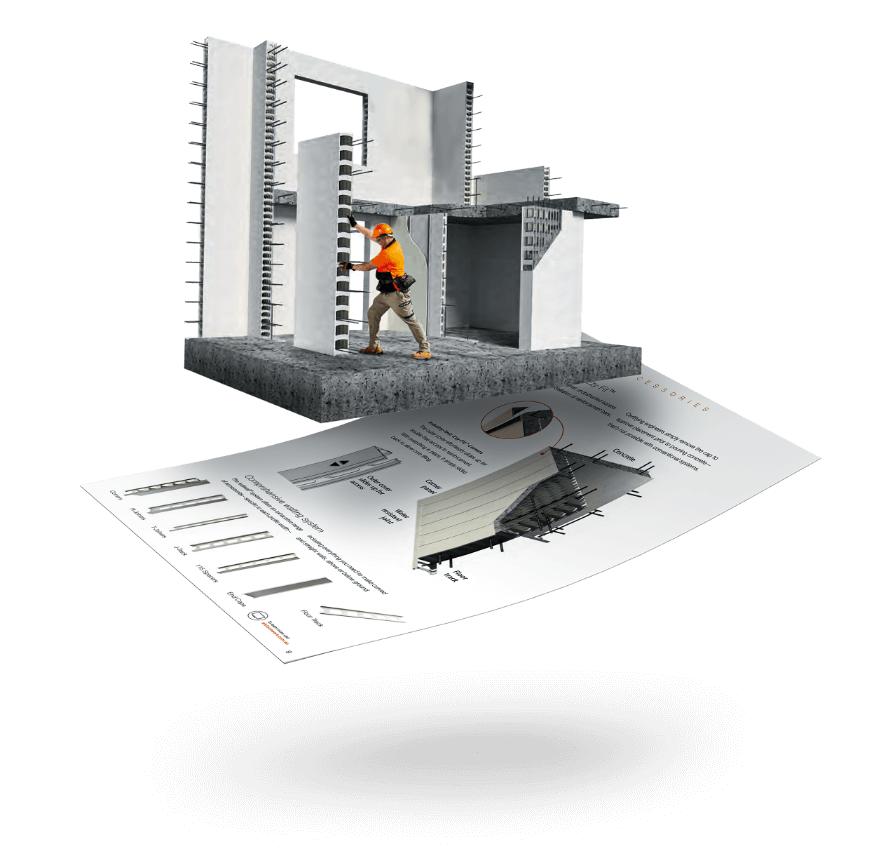

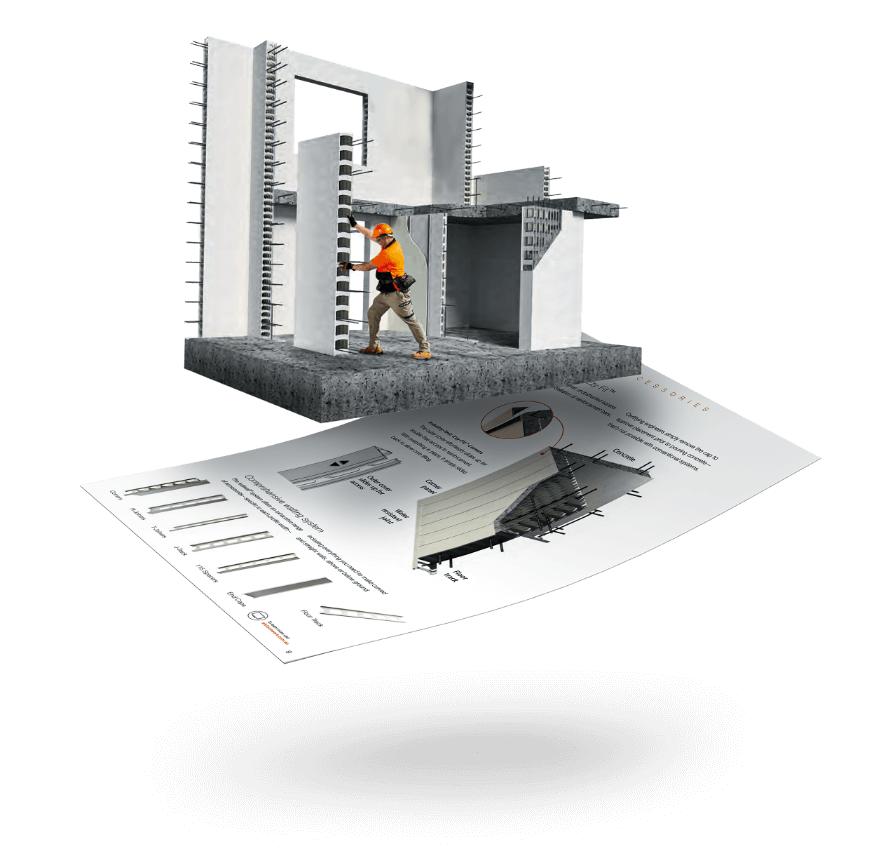

LogicWall® panels are a fibre cement based walling system, ideal for multi-residential projects.

The panels provide reliably flat, true surfaces to help deliver high quality finishes. There’s no need for strapping and lining, you can paint directly onto the panel.

With a full supply and install team, you have one less thing to worry about on site.

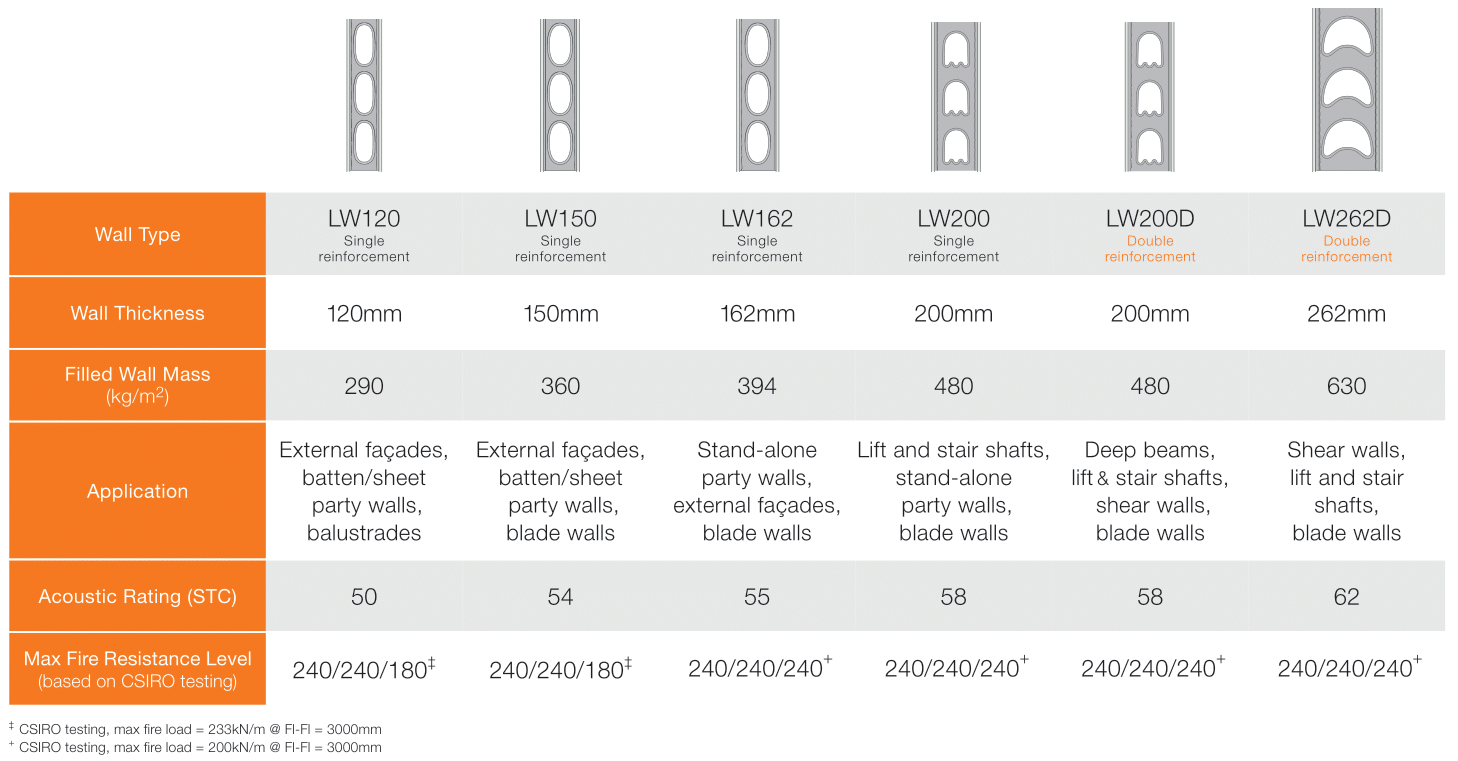

Performance overview

When making the choice of which concrete wall formwork solution to go with, you need to know from the outset that the product meets the criteria of even the most stringent building code standards. With single and double reinforcement options, there is a logicwall® panel that is right for your project.

Masterspec Partner

Masterspec work sections available to easily add to your project.

Logicwall Demo

Watch our short 3min video on Logicwall® .

The intertenancy wall system with a 8-10 week lead time that keeps your projecting moving.

We work with your technical plans to swap out slow precast or blockwork for Logicwall®.

Reduce delays.

Finish faster.

Whether you’re a developer, building contractor, architect or engineer, you know that the cost and timeline pressures of today’s fast-moving construction industry mean you need to work with smart solutions that meet strict standards, yet assist with swift project completion.

Helping to reduce onsite labour requirements and construction times can be a significant factor for being repeatedly contracted as a trusted partner. With logicwall®, a cutting edge lightweight permanent formwork system, you can achieve both objectives, with the best substrate results for quick and attractive finishing.

Shop drawings and panel ID

- AFS Logicwall® is a shop-drawn system and is custom manufactured to suit the design of each project. This means we can accommodate columns, beams, corners, raked walls, sills and lintels on your project.

- The shop-drawn logicwall® system will dramatically reduce waste and mess onsite compared with traditional construction methods such as block work.

- Each panel is labelled with a Panel ID code that corresponds with the shop drawings. This allows for enhanced coordination in delivery and installation stages.

Delivery

- AFS Logicwall® is freighted to the site in bulk quantities of up to 185m² per load

- The panels are flat stacked, creating pallets which can be craned by a custom-made pallet lifter or Manitou onto the floor slab, ready for placement.

Panel Installation

AFS Logicwall® is renowned for its speed of construction and its ability to deliver large structures in record time

Step 01 - Floor track

Floor track is fixed to the marked out slab over reinforcement starter bars.

Step 02 - Easy lift

Panels are erected by hand – teams of three men per panel, using a set technique.

Step 03 - Alignment

Panel joiner stud is aligned with the standing panel.

Step 04 - Install

Standing panel is lowered down over the reinforcement starter bars.

Step 05 - Secure

Panel is locked into place over the floor track.

Step 06 - Bracing

Walls are temporarily braced at panel joints with purpose-built adjustable braces.

Step 07 - Reinforcement

Vertical and horizontal reinforcement bars are placed in walls to project engineer’s specification.

Step 08 - Wall straightening

Panels are plumbed and straightened with levels and string lines.

Step 09 - Electrics

Electrical conduits are installed from the top of the panel.

Step 10 - Plumbing

Conduits and pipes for plumbing services are generally attached to the wall which is strapped and lined.

Step 11 - Core filling

After the installation process is complete the panels are then core filled with concrete using concrete pumping methods, generally using a boom pump.

Reinforcement and services integration

Reinforcement

Vertical and horizontal reinforcement bars are placed in the walls to project engineer’s specification.

Electrical services

Conduits are installed from the top of the panel prior to core filling. Electrical boxes are attached to the conduit and secured with a face cover place.

Plumbing services

Conduits and pipes for plumbing services are generally attached to the wall, which is battened and sheeted.

Concrete core fill

After the installation process is complete the panels are then core filled with concrete, generally using a boom pump. Core filling is mostly performed from the formed deck of the next slab or off a scaffold. The concrete walls are then ready to perform as a load bearing structure for the next floor slab or roof structure.

Wall Finishing

Eliminate the cost of additional trades normally needed for plastering or any other veneer application. AFS Logicwall® is an all-in-one permanent formwork system for building, engineered load-bearing functionality and ready for cosmetic application of finishes for completion of a job. The clean flat fibre cement finish of logicwall® provides an excellent substrate for a range of external and internal acrylic render and painting systems. For internal party and corridor wall applications, logicwall® offers hard-wearing impact-resistant and solid concrete-feel walls which add value to the overall development.

Internal wall finishing

- Walls can be finished by joint setting only, joint setting and skim coating, or lining with plasterboard. AFS recommends skim coating for walls which are subject to glancing light only.

- The walls are then ready for applied finishes and painting with recommended leading brand products to deliver quality masonry-feel walls for a range of applications.

External wall finishing

- AFS offers several external slab junction details to prevent water entry and to suit the architectural design of the building.

- We strongly recommend the application of an acrylic render system to external walls. This assists the concealment of joints and surface imperfections that may be visible in glancing light conditions.

De-risk your next project

Leave your details below and we’ll get in touch about how we can de-risk your next project using AFS LogicWall®